Mapping And Validation Services

Temperature mapping is essential for monitoring the temperature throughout the system for sectors and industries where incorrect or fluctuating temperatures can affect final product quality and compliance with industry standards. It’s crucial for ensuring that the cooling system can adequately control the temperature of each specific product.

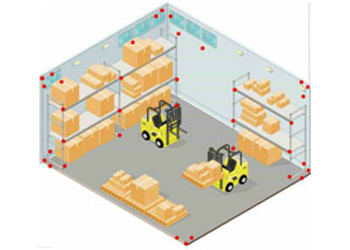

Warehouse & Storage Areas Mapping

- Cold Room, Freezer, Chiller – Mapping & Validation

- Stability Chambers & Incubators Mapping & PQ

Businesses involved in food or pharmaceutical storage need to maintain specific temperature ranges in warehouses, refrigerators and cold-storage units. Variations of even a few degrees can impact product quality. For instance, if a certain storage area is too cold, products may freeze and get damaged. If it’s too warm, they lose efficacy or even become unsafe for consumption.

Creating a temperature profile of critical storage equipment or locations is essential, and a critical part of managing risks related to product quality and increasing patient safety. To balance the returns from your investment, you may have to balance these elements combined with the costs of packaging and your environmental monitoring programs, against your staffing requirements.