Your partner in Weighing Solutions, Material Handling & Lifting Equipment

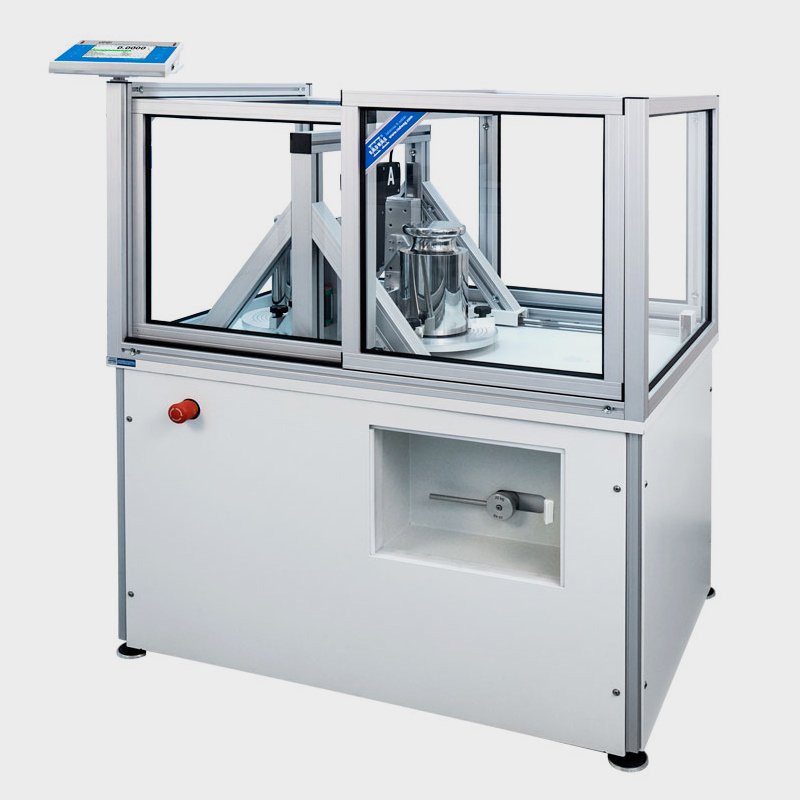

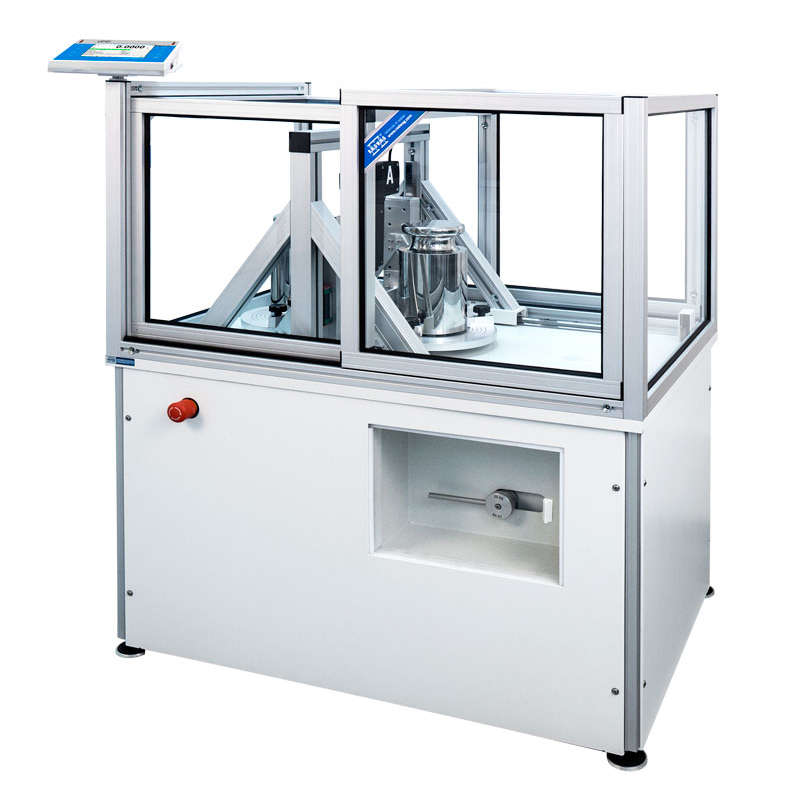

Automatic Mass Comparators

| Maximum capacity [Max] | 10,2kg |

| Readability [d] | 0,1mg |

Description

Application:

Mass comparator AKM-2/10 series featuring automatic mass loader enables automatic determination of mass deviations of a single weight in a single cycle. The system of automatic mass comparator is commonly applicable in mass measuring laboratories, and particularly in certification units for weights classes E and F.

Design and Functionality:

The supervising part of a mass comparator is a digital module which cooperates with a controller of instrument’s mechanical components. The automatic mass loader features a basis with self-centring fields, a robot and a steel body. The digital module and the robot are located in mass comparator’s weighing chamber. The loading robot is controlled by the computer’s controller. The instrument is operated by means of digital display which is plugged to mass comparator’s controller.

Lengthwise shift of the loading robot with weights is carried out automatically using solenoid actuators. Additional software functions enable loading and taking off the weights, data processing and storing, and data export to instrument’s memory.

Specification

| Maximum capacity [Max] | 10,2 kg |

| Readability [d] | 0,1 mg |

| Weighing pan dimensions | ø90 mm |

| Repeatability at low load | 0,2 mg (500 g) |

| Repeatability at nominal load | 0,2 mg (10 kg) |

| Stabilization time | 30 s |

| Operating temperature | +10 ÷ +30 °C |

| Power supply | 110 ÷ 230 V AC / 50 ÷ 60 Hz / 13,5 ÷ 16 V DC |

| Packaging dimensions | 1050×800×1320 mm |

| Atmospheric humidity | 40% ÷ 60% |

| Electric compensation range | - 100 ÷ + 200 g |

| Adjustment | external |

| Working temperature change rate | ± 0,5 °C / 12 h (± 0,3 °C / 4 h) |

| Atmospheric humidity change rate | ± 2 % / 12 h |

| Weighing device dimensions | 950×650×1150 |

| Controling device dimensions | 206×140×70 mm |

| Net weight/gross weight (comparator) | 30 kg / 59 kg |

| Net weight/gross weight (automat) | 230 kg / 350 kg |

| Supplementary weights internal | half automatic |

| Supplementary weights external | - |

| M2 | - |

| E1 | 2 kg ÷ 10 kg |

| E2 | 500 g ÷ 10 kg |

| F1 | 500 g ÷ 10 kg |

| F2 | 500 g ÷ 10 kg |

| M1 | - |

| Eccentricity (tested load) | 0 mg |

Repeatability is expressed as a standard deviation determined for 6 ABBA cycles. Standard deviation is experimentally determined under ambient conditions for calibration of E1 class mass standards specified in OIML R111 (Table C.1.) document.

Accessories

RMCS System

Receipt printer

Ambient Conditions Modules

RS 232 cables

(scale - Epson printer)

RS 232 cables

(scale - computer)

Barcode scanners

Copyright @2021. ENDEAVOUR INSTRUMENT AFRICA LIMITED.